Products

Specialised Stamping and Plating

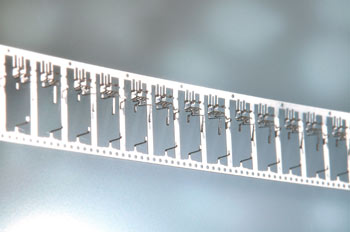

Custom stamping and plating is at the heart of Batten & Allen’s

business. We have worked with clients to create specialised product

applications in a wide variety of fields, including the Medical, Telecom,

Automotive and Electronics industries.

Batten & Allen is a focused producer of precision stampings, rather

than a general job shop. We aim to ensure our expertise is not diluted.

With multi-out dies and constant speeds of up to 1,200 strokes per minute

– based on a 3-shift work schedule – we have the capacity to produce up to

six hundred and fifty million stampings per month with our complement of

Bruderer presses.

Our expertise extends to assisting customers with the initial design

concept, including the choice of raw material. To this end, we have

developed close working relationships with industry leading producers of

non-ferrous alloys. Where possible, we like to be involved before a part

is signed off so that we can assist in the design and product layout. In

this way, we can attempt to identify “cost-down” solutions before a die is

built.

Following manufacture of the stamped and plated part, we can also offer

crop and form tooling to assist customers’ in-house assembly and

production. We are aware of EU directives on lead reduction as applied to

post electroplating, and we are able to offer advice on alternatives to leaded

solder alloys.

Plating Shop: 3 Standard Electroplating Lines 4

Selective Electroplating Lines 1 Wire Electroplating Line

(160M/Min)

Press Shop: 25 Bruderer Presses 4 × 25 tonne – max speed

1500 spm 9 × 20 tonne – max speed 1800 spm 8 × 30 tonne – max

speed 600 spm 4 × 30 tonne B300-75 CNC – max speed 1400 spm

Full

Equipment List

|

Medical stamping, Medical pressings, Precision metal

pressing, Precision metal stamping, Metal pressings, Metal stamping,

Miniature pressing, Miniature stamping

|